- Neometals has announced its pilot test-work generated high purity cobalt sulphate at a high recovery rate that exceeded over 98 per cent

- The cobalt sulphate has exceeded the company’s expectation and represents a significant milestone in its technology

- The recycling plant is targeting a 90 per cent recovery of lithium-ion battery materials

- The company now aims to target the recovery of nickel sulphate leaving lithium as the last element to be extracted

- On market close, Neometals remains steady, trading at 19¢ a share

Neometals has provided the market on its lithium-ion battery (LIB) pilot test-work.

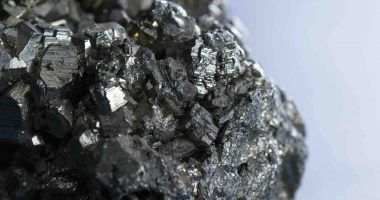

The company has announced its pilot test-work generated high purity cobalt sulphate at a high recovery rate that exceeded over 98 per cent.

The cobalt sulphate has exceeded the company’s expectation and represents a significant milestone in its technology.

The pilot test-work is being undertaken by SGS Canada. The test-work represents part of a pre-development for a proposed LIB recycling plant.

The recycling plant is targeting a 90 per cent recovery of LIB materials from electric vehicles and consumer production scrap and end-of-life cells.

During the Feed Preparation Stage of the pilot, Neometals successfully shredded and processed 2.3 tonnes of spent commercial LIB.

A total of 980 kilograms of unbeneficial mixed cathode and anode materials (Black Powder) were fed into the Hydrometallurgical Processing stage, from which cathode metals are currently being recovered and refined into high-purity chemical products.

“The Hydrometallurgical Processing stage leaches the Black Powder and sequentially recovers cathode materials which are refined to generate high-purity chemical products for sale directly into the battery supply chain,” the company said.

Neometals said that the pilot test-work program is nearly completed as it has recovered copper, manganese and now cobalt sulphates. It says the recovery of nickel and lithium into sulphate products will commence very soon.

Managing Director Chris Reed congratulates Neometals technical team on this achievement.

“It represents the most significant technical milestone in what has been a very comprehensive Pilot campaign to deliver the most robust, eco-friendly recycling solution to the lithium-ion battery supply chain,” Chris said.

“Our strategy of disciplined evaluation with business model flexibility has attracted a multi-billion dollar equipment manufacturer to consider a 50:50 JV to fast track commercialisation,” he added.

The company now aims to target the recovery of nickel sulphate leaving lithium as the last element to be extracted.

On market close, Neometals remains steady, trading at 19¢ apiece