- Volt Resources (VRC) receives results from battery cycle test work using natural graphite from its Bunyu Resource in Tanzania

- VRC has completed 170 cycles of its testwork program, which was designed to develop a technical support data package for market introduction of the Bunyu graphite product

- The results show a low irreversible capacity loss which means it’s suitable for use in the production of battery ready anode material for energy storage solutions

- Volt’s next step is to conduct feasibility studies for the development of battery anode production facilities in Europe and the USA

- Shares in VRC have been 3.6 per cent higher trading at 2.9 cents

Volt Resources (VRC) has received results from battery cycle test work using natural graphite from its Bunyu Resource in Tanzania.

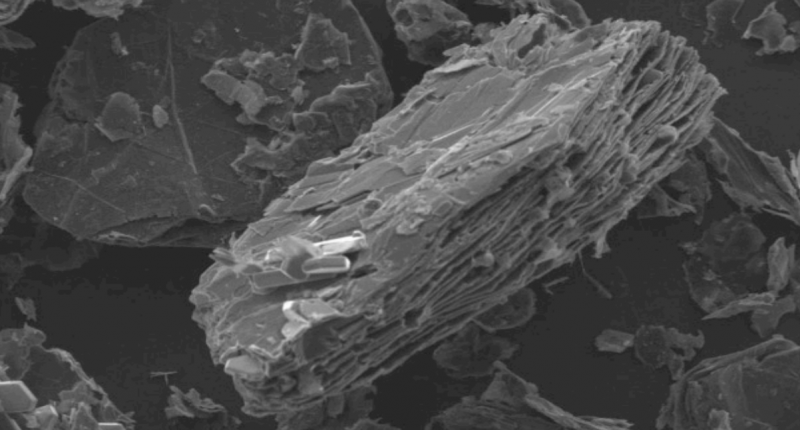

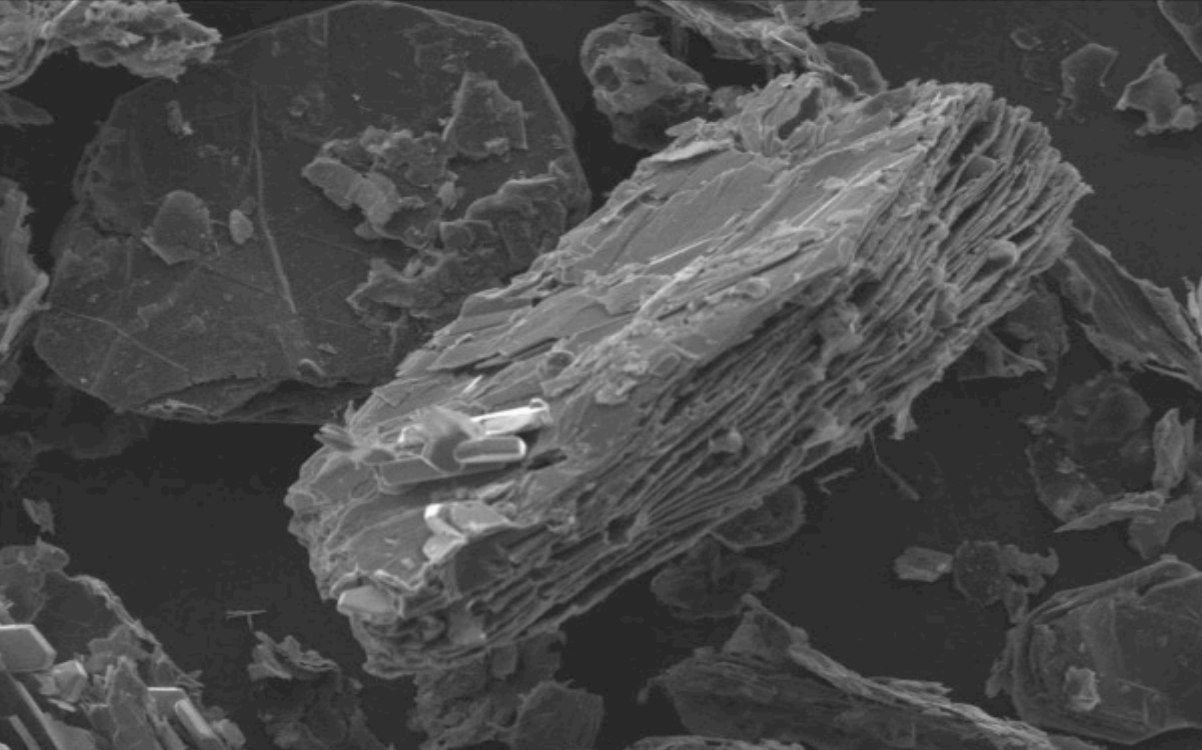

The company has so far completed 170 cycles of its battery cell testwork program which was designed to develop a technical support data package for market introduction of the Bunyu graphite product.

Additionally, VRC is looking to develop the provision of battery-ready material for samples to be provided to potential lithium ion battery manufacturing customers.

According to the company, the latest results show very low irreversible capacity loss after 100 cycles and the continuation of low capacity loss.

The low capacity loss is said to relate to battery life and Volt said this measure is a key performance indicator for battery anode material to be used in the production of lithium-ion battery technologies.

Volt’s Managing Director, Trevor Matthews said the company is delighted with the results which were compiled by commercial graphite producer and processor, American Energy Technologies.

In particular, he said the results confirm that Bunyu’s flake graphite is suitable for use in the production of battery-ready anode material for energy storage solutions.

Moving forward, the results will assist the company’s discussions with battery manufacturers and technology groups as it progresses battery-ready coated spherical anode-grade graphite production plans in the USA and Europe.

In addition to feasibility studies, plans are underway for an evaluation and sampling program with a number of technology and battery end-user groups.

The aim of this work is to further VRC’s commercialisation objectives in the electric vehicle, consumer and energy storage battery platforms in Europe, the United States and Asia.

In progressing towards commercialisation, Mr Matthews said Volt will be adopting the inverted flow sheet for its downstream operations.

“The use of this flowsheet will allow us to not only convert a significant portion of our graphite into batteryready anode material for lithium-ion batteries, but will also generate a range of ultra-high purity by-products for use as electrically conductive diluents in battery cathodes and in a variety of valuable non-battery applications,” he explained.

Shares were trading 3.6 per cent higher trading at 2.9 cents at 10:24am AEST.